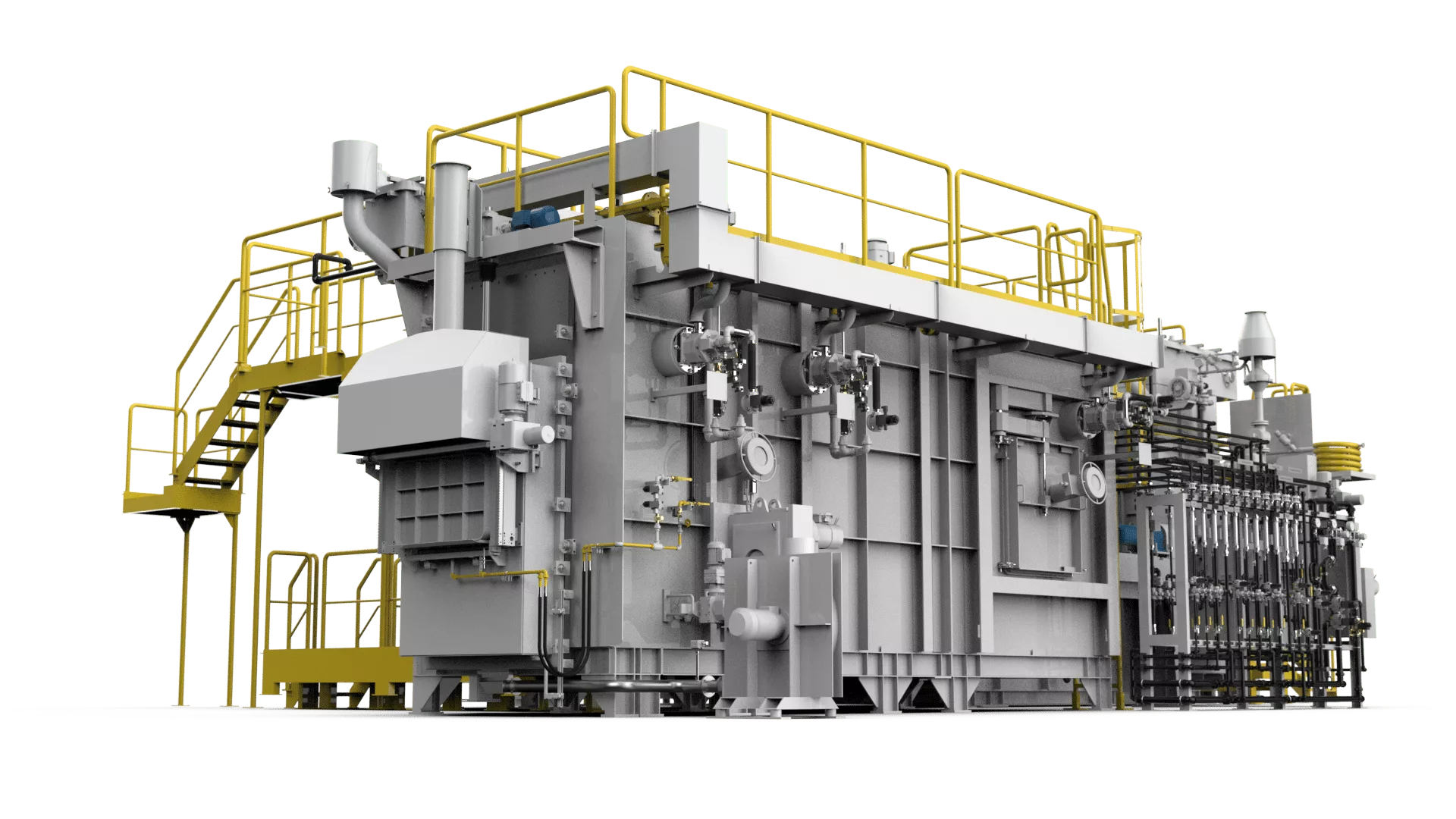

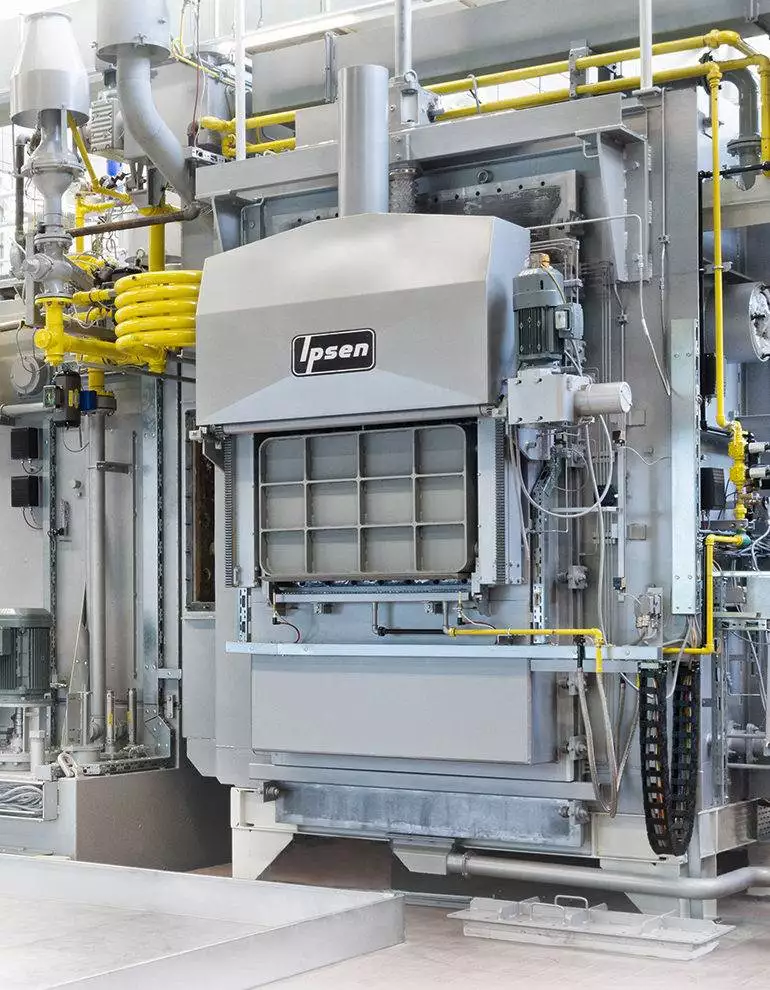

Atmosphere Furnaces

Precision engineering for high efficiency and throughput.

If you need an atmosphere batch furnace, continuous furnace or the latest atmosphere software technology, we can create a solution that elevates your capabilities.

Start Your QuoteFurnaces that strengthen your metals. A partnership that strengthens your business.

Furnace Specifications

Batch Furnaces

Enhance your precision and capacity in an efficient footprint with our standard or custom-built batch furnaces.

Continuous Furnaces

We’ll help you determine the right continuous furnace for your needs. We build pusher, rotary hearth and mesh belt style continuous furnaces along with endothermic generators to accommodate all types of heat treating applications.

Multi-Purpose Chamber Furnace Processes

- Hardening with oil or salt quench

- Carburizing and case hardening

- Carbonitriding

- Carbon-free annealing

- Nitriding

- Ferritic nitrocarburizing (FNC)

Tempering Furnace Processes

- Tempering

- Annealing

- Nitriding

- Ferritic nitrocarburizing (FNC)

- Preoxidation and postoxidation

- Preheating

- Stress relieving

We can build your atmosphere furnace with one of three gassing system options:

- Endothermic gas via generator with Ipsen Endosafe®

- Nitrogen/Methanol

- Direct gassing with hydrocons and air Ipsen SuperCarb®

The standard sizes and capacities of our standard size furnaces are as follows:

Medium

WxLxH: 610 x 910 x 760 mm (24x36x24 in)

500 kg (1,100 lb)

Large

WxLxH: 760 x 1,220 x 760 mm (30x48x30 in)

1000 kg (2,200 lb)

Extra Large

WxLxH: 910 x 1,220 x 910 mm (36x48x36 in)

1,500 kg (3,300 lb)

XXL

WxLxH: 1,220 x 1,520 x 1,300 mm (48x60x51 in)

2,000 kg (4,400 lb)

Special heights and increased load weights are available on request.

You can specify the quench media of your choice when configuring your Ipsen atmosphere furnace. Our models offer both integral and external quenching options and can accommodate caustic media, oil, or salt quenching. No matter which media you choose, you’ll rest assured that each process will receive a uniform quench for minimum distortion and high part quality.

We also offer add-on technology such as Ipsen TurboQuenchTM and Ipsen SuperQuench® to make your furnace as easy to operate as possible.

Start Your Project

Expand your capacity. Add capabilities. Grow your business.

Reliable, precise, long-lasting atmosphere solutions.

Blog Post

Conversion From L to H Gas: What Does This Mean for My Heat Treatment Operation?

By Matthias Rink – Ipsen International GmbH You may be affected by the requirement to convert from L (low-calorific) to H (high-calorific) gas by 2030. You can find out if…

Read More

Get in touch with an atmosphere furnace expert today.

We will help you maximize your next atmosphere furnace investment so it brings the greatest possible value to your business. We start every solution with a full understanding of what you need to accomplish. Connect with us today.

Get Started