Diffusion Pump

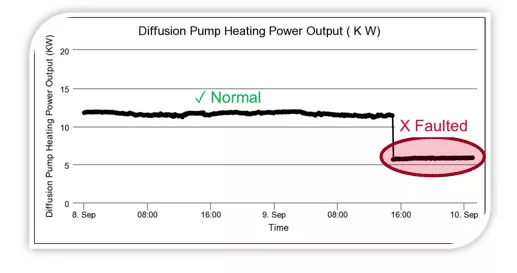

PdMetrics® continually monitors the health of the diffusion pump by observing water and oil temperature, and making sure the power output is within the proper range (as seen on the dashboard below).

In the example below, PdMetrics® detected a low kilowatt reading on a customer’s diffusion pump heater and sent an email notification to the customer. They were able to check the heater and correct the condition before it had a significant impact on production and/or caused decreased part quality.

A diffusion pump with a faulty heater may lead to poor vacuum levels, inability to hold against normal outgas loads and potential oil vapor back-streaming into the hot zone.

Roughing Pump

PdMetrics® also monitors the roughing pump oil temperature and exhaust pressure. When a customer was alerted to an increase in the exhaust pressure, the maintenance team was able to look at the PdMetrics® dashboard for further explanation of the required maintenance — in this case to check/replace the roughing pump filter.

By providing this information in real-time, customers can take action early, avoiding:

- Increased pumping downtime

- Decreased pumping performance

- Roughing pump damage

With PdMetrics®, maintenance operations are based on actual usage and wear, as opposed to a fixed schedule, saving maintenance teams time and unnecessary expenses.