When working with heat-treating furnaces, it is critical to validate your equipment to ensure uniformity, reliability and repeatability. By utilizing the proper methods of preventive maintenance, you can ensure a longer life for your furnace and better prepare for future maintenance or repairs.

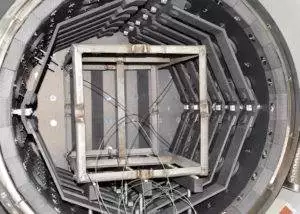

One of the most important tests you can perform to validate your furnace is a temperature uniformity survey (TUS). A TUS is a test, or a series of tests, that measures the temperature variation within the furnace’s effective work zone before and after thermal stabilization. You should always perform an initial TUS prior to the first use of the furnace.

On average, you should perform a TUS no less than twice a year. Of course, how often you perform one depends on the specifications you subscribe to and the overall performance of your furnace.

When a TUS does fail—meaning the temperature is not where it’s supposed to be—it signals that your hot zone is starting to degrade. On average, hot zones should be replaced every five to seven years.

Other forms of furnace validation include leak detection and system accuracy tests (SAT). When it comes to leak detection, you should always know the linear leak rate for your furnace, as well as perform a leak check anywhere from once a week to once a month. Overall, by knowing the leak rate and performing a leak check you are able to verify the integrity of your vacuum. You should also perform a weekly SAT to validate the accuracy of the control thermocouple. Other forms of preventive maintenance that are important to perform include regular pump maintenance and cleanup cycles.

In addition to validating your equipment prior to use, having accurate records is also crucial to maintaining an efficient and effective maintenance program. After you start up your equipment, it is important to carefully maintain a performance log that records the following:

- Blank-off pressures of the mechanical pumps

- Pumpdown time to a given pressure

- Ultimate vacuum

- Leak-up rate for when the chamber is blanked-off

For other useful maintenance tips, refer to our checklists for preventive maintenance to be performed daily, weekly, monthly and semiannually.