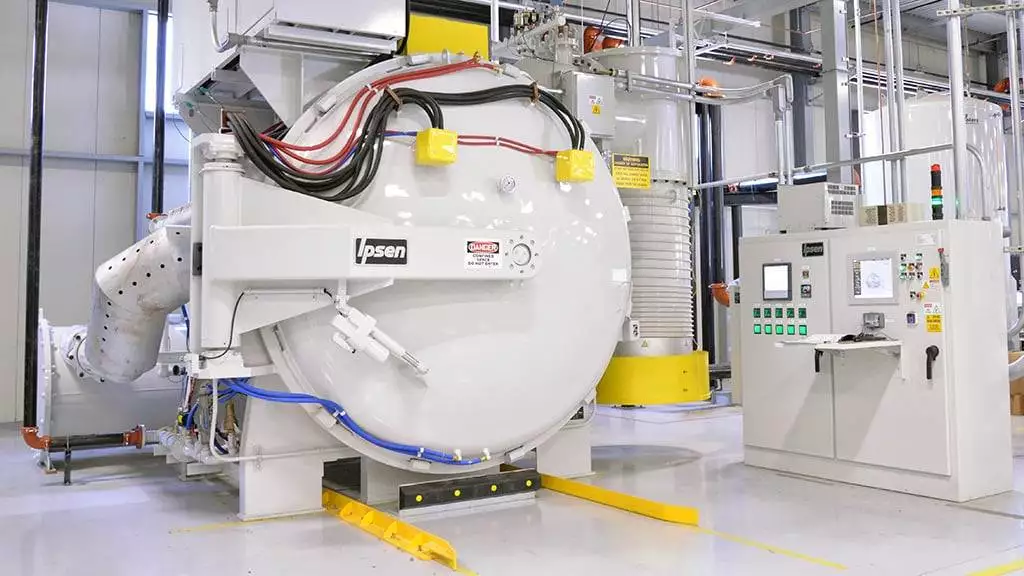

Choosing the right furnace is critical for the success of your business and the quality of your parts – and there are a lot of choices available. When purchasing a new piece of heat-treating equipment, here are three essential tips to consider during your research.

1. Assess Your Needs

Before purchasing a furnace or upgrading an older one, the first step is assessing your process and production needs. There are many types of furnaces available and you want to be sure you are investing in the one that best meets your needs. For example, do you have stringent industry regulations (e.g., AMS 2750, Nadcap, CQI-9 or others) that you need to meet?

One common misunderstanding is that you can purchase a furnace that is AMS 2750 or Nadcap certified. In actuality, it is the responsibility of the end user to first, purchase a furnace that is capable of meeting the required industry regulations and second, to operate, maintain and test the equipment so that you can prove your process and capabilities meet the requirements of the certification process.

When assessing your needs, another consideration to keep in mind is which class of furnace you will need in order to achieve your industry requirements. In some cases, there may be very few regulations, but in other cases – such as AMS 2750 and Nadcap – there are very strict guidelines for temperature uniformity, data recording and much more. So you’ll want to purchase the right class of furnace that will allow you to meet these guidelines.

Furnace Classifications

Vacuum furnace systems are classified into six categories: Class One through Class Six. Class One has the most stringent requirements with the smallest range in temperature uniformity, while Class Six applies the least restricted furnace requirements and the widest range of temperature uniformity. The range of temperature uniformity varies from ±5 °F (±3 °C) to ±50 °F (±28 °C).

So if a furnace manufacturer claims their furnace is certified for a certain industry standard, be sure you are clear on which class the furnace is and if it is truly capable of achieving the standards you need to reach. It may be true that a lower furnace class can meet some of the certification requirements – for instance, you may be able to meet one or two of the specifications outlined – but there may be a few requirements that the equipment, if it is the wrong class, may never be able to achieve regardless of how you operate or maintain your furnace.

In the end, it is your particular process and the desired results that will determine which class of furnace works best for you. Therefore, it is imperative that you know what you are trying to achieve, as well as the part material and geometry you will be heat treating.

2. Research Furnace Options

The next step in choosing the right furnace is to determine which options you will need for your furnace. This is also very dependent on your process, parts and certifications you may need to achieve. Regardless of the requirements you are trying to meet, controlling your process and measuring your results will allow you to continually improve your heat-treating results so that you can perfect and maintain a high standard of quality in the parts you produce.

Some furnace options to consider are:

- All-metal or graphite hot zone – you will want to choose the right hot zone configuration for your process and material, as well as any other factors, including energy savings, longevity and so on.

- Convection – depending on your part geometry and load configuration, this option may help you achieve better uniformity in heating your parts and help decrease your cycle times.

- Water system – when it comes to protecting your investment, one of the most critical components is making sure you are using the proper water system for your equipment.

- Loader – this feature allows you to load parts with precision and avoid breaking or damaging expensive heating elements within the furnace’s hot zone.

- Gas accumulator tank – quench with peace of mind knowing the furnace is being supplied with the correct amount of gas and sufficient gas pressure.

- Diffusion pump – depending on your process and industry regulations, you may need a deeper vacuum; this is when you would consider adding a diffusion pump.

- Spare parts kit – avoid downtime by keeping critical or long-lead spare parts and maintenance items in your inventory.

3. Consider Advanced Controls Technology

Finally, you should also learn more about the available controls technology when you are attempting to choose the right heat-treating furnace. These various technologies may be included or optional additions. Again, the choices you make should be based on the processes you will run in the furnace, the material of your parts, and the requirements of your company, your customers and/or your industry.

Maintenance, safety and ease of use should also be considered when choosing a new furnace or upgrading an older furnace. For example, in many older furnaces, a manual adjustment of the heating elements via trim pots is required but, with a controls upgrade, you can monitor and adjust the heating elements through the industrial computer’s interface, making it safer and free from human error.

From simple optimization to automating processes for precise, repeatable results, there are a variety of controls options:

- Hygrometer – not only will you be able to gain more precise control over your process under a variety of conditions, but you will also be able to monitor the moisture content of your process gas.

- Vacuum gauge – accurate, repeatable results can be achieved by monitoring the vacuum and partial pressure levels throughout the heat treatment cycle with this gauge. This is also a requirement of some industry specifications, such as AMS 2750.

- Digital data recorder – this is an advanced data collection, storage and report device that allows you to monitor and track your results, as well as create a historical record and backup of your data. By measuring data, you can adjust and perfect your process and keep track of your furnace’s performance over a period of time. This can help you predict when maintenance will be required and avoid unexpected downtime.

- Supervisory Control and Data Acquisition (SCADA) systems – furnace users can view data and operational settings for multiple furnaces at the same time on a single display, thus providing more flexibility for collecting and reporting data in one central location.

- Network connectivity – review in real time the necessary data critical to meeting your heat treatment process, including email notifications of alarms, monitoring of the Programmable Logic Controller (PLC) inputs and outputs and firewall capabilities. This intuitive controls upgrade also allows field service technicians to remotely view your equipment and recommend adjustments, thus preventing downtime and decreasing maintenance expenses.

There are other options and things to consider when buying a new furnace or upgrading an older one, but these tips will help you get started. Always keep in mind your process, parts and industry regulations as you begin your research. Choosing a furnace is a big investment, one that, if chosen wisely, can streamline your processes and save critical time and resources.