With a broken down pottery kiln, an engineering degree from Brown University and an entrepreneurial spirit, Harold Ipsen founded what is today the leading manufacturer in the heat-treating industry. Ipsen has come a long way since 1948, but it started with Harold’s vision of creating products and technologies that shaped a future of thermal processing excellence. With more than thirty patents to his credit, his inventions revolutionized the heat-treating industry and provided the foundation for all that we do here at Ipsen. Let’s take a look at the first patent that started it all.

The first patent Harold Ipsen received was for a muffle/retort style furnace in October 1952. His invention helped better control the hardening process through a furnace design that maintained more uniform heating and avoided cooling of parts before quenching [1].

Ipsen’s inventions enabled his customers to cost effectively produce clean, uniformly processed components. This led to growth in business across the U.S. and Europe. He even participated in a research project for NASA, which involved the production of more stable metal foams [2].

By the end of the 1950s, Ipsen’s customers included manufacturers of automobiles, washing machines, typewriters and airplanes. In the early 1960s, Ipsen expanded the business by manufacturing vacuum furnaces for various technologies including rocket and spacecraft construction [2].

Vacuum Furnaces Get a Turbocharged Makeover

Fast forward to 1985 – the TurboTreater vacuum furnace, designed by Ipsen’s Chief Engineer Craig Moller, was introduced to the market. Moller holds four patents related to this design.

Prior to the merger of Ipsen and Abar, Ipsen only had vacuum furnace designs with rectangular hot zones and internal gas cooling systems, and Abar only had vacuum furnace designs with round hot zones and external gas cooling systems. The Vice President of Sales at Ipsen challenged the engineering group to design a vacuum furnace with a round hot zone and an internal gas cooling system to capture the advantages of both designs [3].

According to Moller, the success of the TurboTreater results from its features. There are no actuated parts in the hot zone, the round hot zone has inherent load geometry flexibility, the compact internal cooling system delivers more cooling gas volume flow per horsepower, and the furnace has a user-friendly controls platform. The heating and cooling performance is also outstanding [3].

Ipsen currently has more than 750 TurboTreater units in the field.

Modern Innovations

Today, Ipsen holds nearly 100 patents in the U.S., thanks to dozens of past and present employees. Some modern inventions include a work load lifting system for a vertical vacuum furnace, load transport mechanism for a multi-station heat-treating system, as well as advancements in convection heating, high-efficiency cooling and gas quenching systems.

These innovations are providing manufacturers with vacuum furnaces that are faster, more compact, more energy efficient, more cost-effective, and provide better temperature uniformity and produce stronger metallurgical results.

The Future of Heat Treating

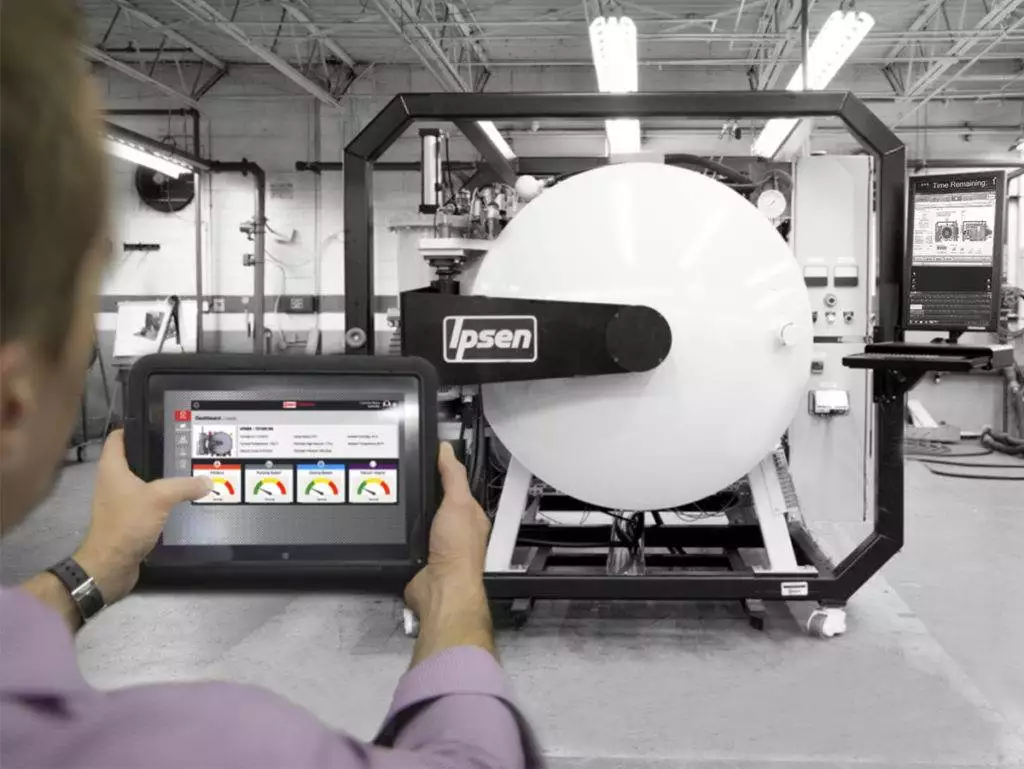

Looking ahead, Ipsen’s innovators are looking to predictive analytics, connected systems, cloud-based solutions, data sharing, augmented reality and automation as new technologies and smart manufacturing become increasingly important in the world of Industry 4.0.

All of Ipsen’s inventors, past and present, have continued to build upon the foundation laid by Harold Ipsen to bring the heat-treating industry into the 21st century and beyond.

“Ipsen’s innovations continue to influence our everyday life … Whether it’s automotive parts, turbine blades or tools, almost all of the world’s leading manufacturers use the technology and heat treatment solutions developed by Harold Ipsen.” [2]

References:

1. Ipsen, Harold. Heat-Treating Furnace. US2615701A. United States Patent Office. 28 Oct. 1952.

2. Reinhold, Markus. “Harold Ipsen – a Pioneer in the Field of Modern Heat Treatment.” Heat Processing, Mar. 2017, pp. 85–86.

3. “Craig Moller, Chief Engineer at ‘Ipsen’ Speaks to the ‘Monty Heat Treat News.’” The Monty, 1 June 2021, https://themonty.com/craig-moller-chief-engineer-at-ipsen-speaks-to-the-monty-heat-treat-news/.