The History of Ipsen in Germany

Joe de Beer never dreamed of Kleve when he came to Germany in 1957 on behalf of Harold Ipsen to find a location for “Ipsen Germany”. After an unsuccessful search in the Ruhr area, he stayed overnight in Kleve and learned from the landlord that a brickyard shed was available for 300 Deutsche Mark (71 USD) monthly rent. The shed was suitable for Ipsen’s needs, and Kleve proved to be a favorable location with plenty of skilled workers and convenient transportation routes.

1957 Ipsen Germany Workforce Statistics

| Office Employees | 3 |

| Production Employees | 7 |

| Salary | DM 2.10/hour (.50 USD/hour) |

| Work Week | 48 hours |

| Vacation Time per Year | 10 days |

In 1960, the company was renamed Ipsen International GmbH. The following year, Ipsen Industries Ltd. was established in England. In 1963, construction on a new production hall was completed in Kleve. The expansion included both manufacturing and office space and was large enough for a 10-ton crane to move heavy equipment from the loading ramp to the railroad cars. In 1964, European expansion continued with the founding of Ipsen Industries SARL in France. Over the next ten years, there would be three more major expansion projects at Germany’s plant before moving to a new location farther south in Kleve around 1975. On February 4, 1991, Kleve’s production shop was destroyed by fire; however, in just over seven months, a new assembly hall was built.

Developments and Innovations

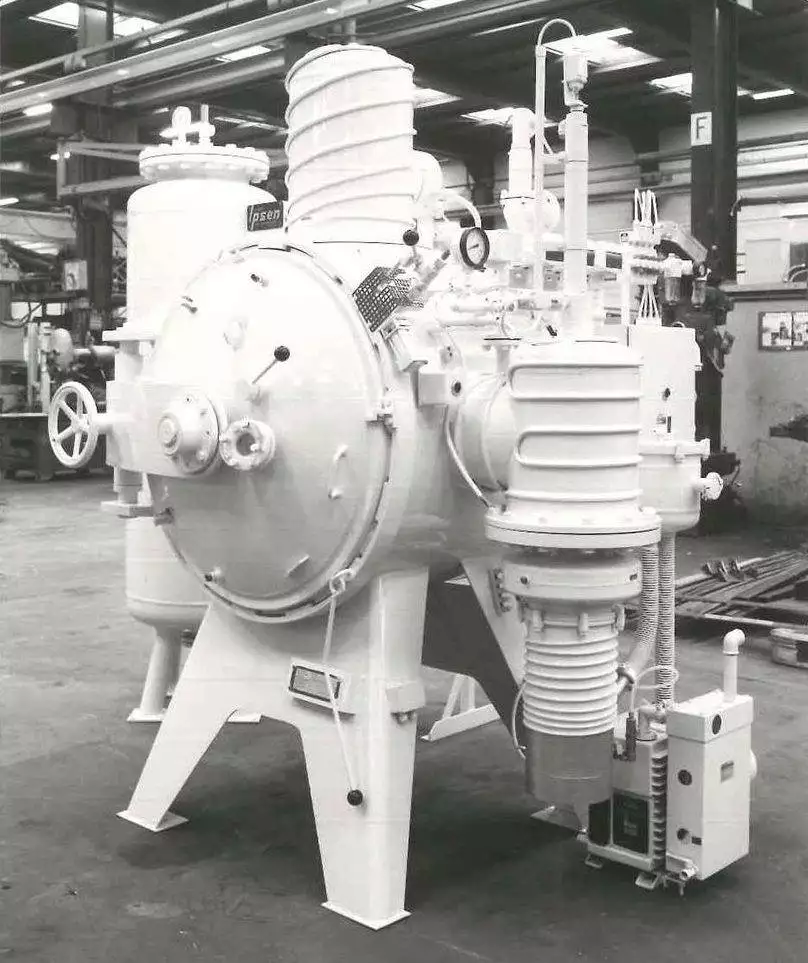

In 1965, Ipsen Germany received their first order for a VFC vacuum furnace (pictured to the right). The following year, they introduced Infratronik, a software for CO2 control.

In 1970, Ipsen Germany delivered their first three-chamber vacuum furnace to Thermi-Lyon in France, a customer specializing in heat treatment and coating services. Ipsen Nordiska AB, Sweden was founded the same year.

In 1979, the Supercarb process was introduced, which provided a more economical solution for carburizing. The process is characterized by its quick, uniform and reproducible carbon transmission.

In 1982, Ipsen Germany celebrated 25 years. During this decade, a carbon sensor was developed to determine carbon potential in atmosphere furnaces, and the AutoMag software was introduced to market. AutoMag allowed customers to automate loads, optimize production capacity, and use energy resources more efficiently.

In 1995, the SolNit (solution nitriding) process was developed for surface hardening of both austenitic and martensitic stainless steels. The process produced stronger parts with improved corrosion resistance.

In 1998, the AvaC (vacuum carburizing with acetylene) process was developed, which provided precise case-depth uniformity for parts with complex geometries.

In 2004, the Recon III burner was introduced, which was more environmentally friendly and produced more uniform heating than previous burners. The same year, Ipsen’s largest chamber furnace (a TQ-37) was shipped to Finland, and in 2007, three more TQ-37s were shipped to a customer in Turkey. Ipsen’s software Carb-o-Prof also came out in 2007, designed to control a wide variety of processes like hardening, carburizing and carbonitriding.

In 2008, the Turbo2Treater was introduced. The vacuum furnace was specially designed for high-pressure quench applications and features a square hot zone.

in 2010, Ipsen Germany received one of their largest orders to date, for an auto parts manufacturer in Georgia, USA. The line included three box furnaces, one quench bath, one washer, two tempering furnaces, one unloader for hot transport and one for cold transport, batch storage equipment, and feed-in/-out stations.

In 2015, the ATLAS atmosphere furnace is brought to market boasting a compact footprint, energy efficiency, cost savings, and high part quality with its advanced quench system design.

Today, Ipsen Germany is focused on providing customers with greater security, safety and sustainability through software upgrades and research and development of new technologies. In 2022, the Recon IV burner was launched to provide customers with energy savings of 10 percent or more, as well as significantly reduce their CO2 emissions. As Ipsen’s Atmosphere Technology Excellence Center, Ipsen Germany continues to set the standard in the industry, providing innovative solutions to customers all over the world.